In today’s volatile and uncertain market, companies can no longer afford to operate without a structured, data-driven approach to forecasting demand. Demand planning is more than just predicting sales—it’s about building an integrated, agile business that can respond to customer needs while managing resources efficiently. Despite its importance, many organizations still rely on outdated tools like spreadsheets or allow bias and siloed decision-making to corrupt their forecast accuracy.

Employing predictive analytics and integrated demand planning can significantly streamline decision-making processes, create new insights, and save several business functions a lot of time and money.

This article explains why businesses need to leverage demand planning to improve their operations and explains the quantifiable value of doing it so that it can be sold within an organization.

Why Focus on Demand Planning?

Most companies that decide to invest in demand planning or improve their process are primarily driven by one or more of the following:

- Forecast accuracy challenges

- A highly variable process that needs improvement

- Need for a more efficient manufacturing or distribution system

- Downstream inventory problems driven by unseen variability

- Desire to improve cooperation between sales and operations

At its core, demand planning synchronizes operations. It allows marketing, sales, supply chain, finance, and production to operate from a common set of assumptions. Without an accurate demand plan, supply planning becomes reactive, finance struggles with forecasting revenue, and customer service deteriorates from stockouts or excess inventory.

Consumer behaviors have become increasingly unpredictable. Economic shifts, global disruptions, and rapid product cycles mean relying on historical sales alone is no longer sufficient. Demand planning introduces a proactive lens incorporating internal drivers (promotions, price changes) and external signals (market trends, customer insights) to create adaptive forecasts.

Inaccurate demand forecasts translate to costly outcomes: expedited shipping, excess working capital, lost sales, and markdowns. Improved demand planning helps reduce forecast error, allowing for better inventory placement, production planning, and supplier coordination. Even a five to ten percent improvement in forecast accuracy can have a significant bottom-line impact.

Potential Improvements Resulting From Demand Planning

Organizations that invest in improving demand planning benefit from:

- Reduced inventory costs through better alignment of supply and demand.

- Improved service levels by placing the right product in the right place at the right time.

- Higher forecast accuracy can lead to more reliable plans across finance and supply.

- Faster decision-making is enabled by real-time data and scenario analysis.

- Greater agility because of the ability to quickly adjust to shifts in demand or supply.

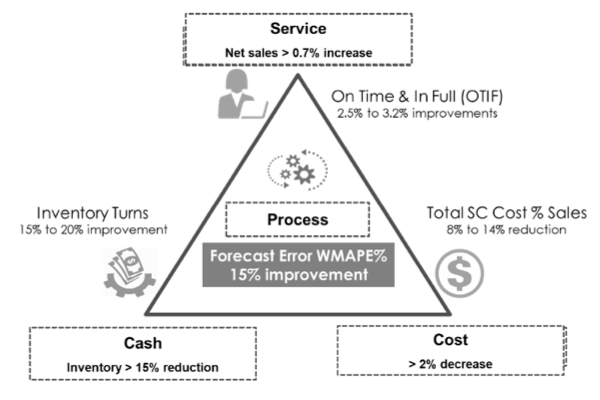

A mountain of research today shows that a mature demand planning process helps improve forecast accuracy and deliver a high return on investment (ROI). Improved forecast accuracy, when combined with software that translates the forecast into meaningful actions, will decrease inventory and operating costs, increase service and sales, improve cash flow and gross margin return on inventory investment (GMROI), and increase pre-tax profitability. The forecasting error, no matter how small it is, significantly affects the bottom line. In our experience, a 15 percent forecast accuracy improvement will deliver a 3 percent or higher pre-tax improvement.

In a previous IBF study of 15 U.S. companies, we found that even a one-percentage-point improvement in under-forecasting at a $1 billion company delivers a savings of as much as $1.52 million, and for the same amount of improvement in over-forecasting, $1.28 million.[i]

The reduction in downstream finished goods inventory resulting from a well-established process and forecast accuracy improvements provides a one-time saving, as well as recurring savings arising from reduced carrying costs. There are great benefits in a make-to-stock or distribution company, the downstream inventory reduction could range from 10 to 20 percent since forecasting inaccuracies typically drive around 75 percent of the required safety stock.

Building and Investing in Demand Planning

Here are some best practices when it comes to demand planning.

- Build an unbiased, unconstrained, consensus-based forecast. Organizations often confuse the demand plan with the sales target. Sales may overestimate to push for stretch goals, while operations may buffer to protect service. Demand planning needs to separate judgment from aspiration. Instituting a formal demand consensus process ensures all voices are heard, but forecasts remain grounded in data and evaluated against actual performance.

- Upgrade from static spreadsheets to dynamic models. Many companies still use Excel as their primary planning tool. While familiar, spreadsheets lack scalability, version control, and real-time integration. Upgrading to a dedicated demand planning system (or enhancing existing tools with forecasting models) introduces automation, improves collaboration, and enables real-time adjustments. It also supports more advanced techniques such as decomposition models or AI-based forecasts.

- Understand and match models to patterns. Not all items follow the same demand pattern. Some are seasonal, some have trends, and others are highly volatile. Applying a one-size-fits-all model can lead to overfitting or underperformance. Instead, classify SKUs by their demand characteristics and apply the appropriate model, whether that’s exponential smoothing, moving average, or more complex causal models.

- Focus on data quality and forecastability. Forecasting is only as good as the data behind it. Cleanse data for outliers, missing periods, and promotions. Measure forecastability using the Coefficient of Variation (CV) or Demand Intermittency. The demand planner becomes the integrator, ensuring inputs from various departments are translated into a structured forecast. Establish accountability through KPIs like bias, MAPE, and forecast value add (FVA).

- Invest in training and improving skills with IBF. Leverage IBF’s certifications, workshops, and learning resources to empower your teams with proven forecasting and planning knowledge, building internal capability that drives consistent, confident decision-making.

Taking steps to practice demand planning optimally will increase the bottom-line benefits you gain from it.

Bottom Line Benefits for Practicing Demand Planning

Many companies leave money on the table with lost sales or poor service levels. An integrated demand planning process can translate to increased revenue of 0.5 percent to 3 percent with improved inventory availability or demand shaping capabilities. Total annual direct material purchase, along with logistics-related expenses arising from demand variability and lost opportunities, can see direct improvements of 3 to 5 percent. We can also benefit from a 20 percent reduction in airfreight costs. The figure below shows the anticipated benefits from a 15 percent improvement in forecast accuracy. (These are averages and individual results for organizations. They are dependent on many other variables and can be higher or lower.)

This illustrates the possible benefits from a 15 percent improvement in forecast accuracy

It is essential to understand that these are average savings amounts. It is up to you to determine what savings you believe you can drive with a mature predictive analytics and demand planning process. Sometimes you need to know what finance and executive leadership anticipate in terms of benefits; you need to be on the same page in terms of expectations. It is here that the Institute of Business Forecasting Advisory Services can shed some light on what is realistic based on past implementations.

Demand planning is not just a supply chain function; it’s a strategic business process that empowers smarter, faster decisions. In an environment where disruption is the norm and expectations are high, companies that implement disciplined, data-driven demand planning will not only survive but also lead.

The Benefits of Demand Planning: The Final Word

The path forward is clear: Separate judgment from strategy, invest in tools and talent, and build a collaborative process that evolves with your business.

In a world of uncertainty, demand planning offers clarity. It’s not just about predicting the future, it’s about preparing for it. Companies that invest in robust, unbiased, and collaborative demand planning are the ones that outperform, outmaneuver, and outlast their competition.

But you don’t have to do it alone.

The Institute of Business Forecasting (IBF) has been the trusted authority in forecasting, demand planning, and S&OP for over four decades. Whether you’re just starting your planning journey or looking to refine and elevate your process, IBF offers the training, certification, tools, and global community to help you succeed.

Join IBF and take the next step:

- Get certified with globally recognized credentials

- Attend industry-leading conferences and events

- Access exclusive research, case studies, and best practices

- Learn from and connect with top planning professionals around the world.

[i] Chaman L. Jain (2018). The Impact of People and Processes on Forecast Error in S&OP. IBF research report #18. August 31, 2018