There’s a huge amount of information on the deployment of S&OP – at the last count there were around 40 million hits on a combined search of S&OP and IBP. Despite all this information and the many years of cross-industry experience of applying S&OP since it was developed in the mid-1980s, the success rate of deployments is still disappointingly low at just 25-30%.

Whilst some of the failures of S&OP deployment become apparent in the first months of execution, it is often the case that engagement and support for the process diminishes over time. Its value is gradually eroded to the point where it is no longer a key process in the organization.

There are two common drivers for this:

- S&OP is fundamentally a cross-functional process, and most organizations are not set up to enable and sustain ongoing cross-functional collaboration

- Important elements such as process design, systems and data provision are frequently not underpinned by critical softer enablers (such as reward and recognition, empowerment or other cultural factors)

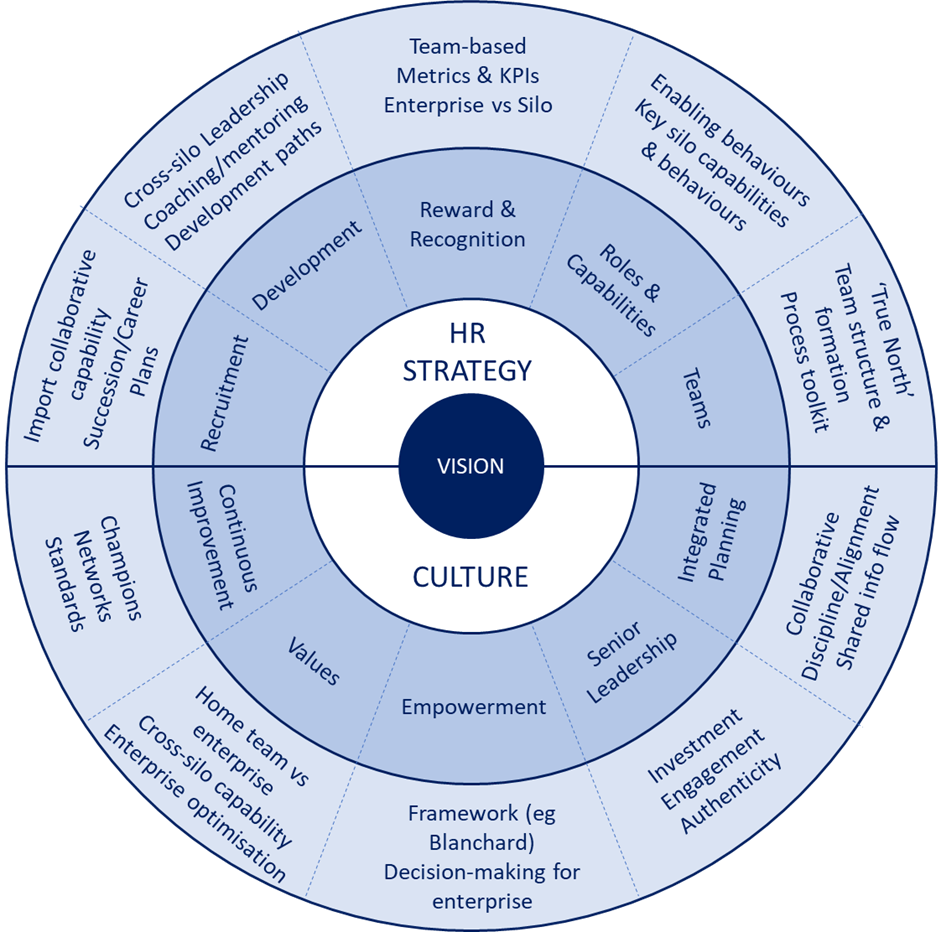

Throughout my career as a commercial leader, IBP leader and General Manager, I have often experienced the challenges in building and sustaining cross-functional capability. As a result, I developed a generic framework to set out the key enablers for this capability which are often missing from deployment programmes. This is summarised in Figure 1 below.

When applied specifically to the challenge of S&OP deployment, this framework highlights three enablers that typically receive inadequate attention:

- Development

- Empowerment

- Continuous Improvement

1. Development

S&OP deployments often focus on the specific technical or functional capabilities to execute the process (and normally with an emphasis on Supply Chain roles such as Demand or Supply Planners). However, in order to provide strategic enterprise support for S&OP, several other aspects of Development are essential:

- Cross-functional leadership – Building and leading cross-functional teams requires a set of specific knowledge, skills and behaviours are often neglected in traditionally organized businesses. This wide range of capabilities is built upon a fundamental understanding of the culture, perspective and goals of the various functions involved. However, it extends beyond this to include building high-performing enterprise teams and leadership capabilities to help functional specialists achieve company-wide goals.

- Tailored support across functions – Equipping every participant in the S&OP process to fulfil their role is of critical importance. In particular, the experience of participants in the first few cycles of a new process fundamentally affects the probability of the process being sustainable. Early problems rapidly lead to disengagement and create a poor reputation for the new process from which it is extremely difficult to recover. Just as significantly, creating the infrastructure to induct and develop new entrants to the process over time is central to ongoing sustainability. It is therefore crucial to invest in engaging approaches to capability building across the various functions involved. Supply Chain roles tend to be relatively well-supported but the roles of, for example, product managers, sales teams and finance analysts must also be considered.

- Development Paths – Most organizations tend to develop leaders along functional lines late. This creates a serious gap in the leadership capability for sustainable S&OP where enterprise leadership is critical at every step in the process cycle. In order to address this, a development and succession planning approach is needed which recognises this need. This approach should develop cross-functional leadership skills at various levels in the organisation structure and across the Supply Chain, Commercial and Finance functions.

2. Empowerment

The most effective and efficient S&OP processes are those which are executed with a clear central principle of empowerment. This drives decision-making to the lowest level in the process and escalates issues for executive level decision-making only by exception. This maximises the pace of the process and drives essential team working behaviours at all levels in order to make enterprise-optimised decisions. It also ensures that where key scenarios or decisions need to be discussed by the senior team, they are able to devote quality time to these rather than being overrun by minutiae which could effectively be managed at lower levels.

This requires two fundamental enablers:

- Information sharing – In order to be fully empowered, an S&OP team needs to share information in a consistent way across the team, with standard definitions, metrics and analyses. This ensures that a scenario is consistently viewed by all team members. Individual teams or functions tend to develop their own approaches to reporting but agreeing a single common approach is the first step to making aligned enterprise decisions. It is also important that the team is very clear on the goals and performance measures for the business so that they can be confident that their proposals and decision-making align with these business goals.

- Clear boundaries – It is also critical that S&OP or IBP participants are clear on their specific role, and that of their colleagues, in the process. In its most fundamental form, this includes a transparent description of where each decision should be taken and, where necessary, any thresholds or conditions that apply. For example, a process might define that a local manufacturing site can make decisions on local inventory within certain limits but beyond those limits an approval may be required at the next S&OP or IBP step. Emphasizing the importance of boundaries in the context of empowerment may seem contradictory but research into high-performing empowered organisations reflects the criticality of this approach. It is of course equally important that these boundaries are respected. This can be a challenge for senior leaders who now are required to participate in a monthly cross-functional process to drive decision making when they may have had the freedom to make wholly independent judgements in the previous environment based on their functional seniority.

3. Continuous Improvement

The real value achieved by S&OP is delivered though the ongoing optimization and alignment of enterprise decisions over time. When set up with the relevant support infrastructure, S&OP also becomes more efficient over time. However, many deployment programmes understandably focus on getting a new process up and running and pay relatively little attention to the critical foundation to sustain and improve the process, thus undermining its ability to deliver value year after year.

A number of specific tactics are useful to secure continuous improvement in S&OP:

- Network of champions – Whilst building a network of change agents or champions is sometimes used as an initial change management approach, it is also a very effective means to maintain energy and focus on a newly-deployed process. Selecting this group of champions based on their ability to lead, communicate and influence, not functional skills alone, is critical. Investing to maintain this network and develop its members provides the means to keep S&OP on the agenda across geographies and functions. This network can be used to identify improvement opportunities and work alongside the relevant expert groups (e.g. IT for systems issues) to continuously build capability and performance in the process.

- Clear ownership of S&OP process standards – In an organisation of any size, it does not take long before a region, manufacturing site or commercial team decide to tweak the standard process. In this context, it is critical that there is both defined ownership of process standards and also a transparent change control process. This ensures that proposals for improvement are not just ignored, but are systematically reviewed and incorporated where suitable into a standard corporate process.

- Audits/Healthchecks – Audits or ‘healthchecks’ are also useful tools to combine the upsides of process innovation and learning (and at the same time mitigate the potential negative effects of lack of process adherence). However, it is essential to set up the audit objectives carefully and transparently (and with full senior leader support) to ensure a focus on continuous improvement and avoid an excessive bias towards simply checking and monitoring adherence.